Laboratoire d'ingénierie des produits, procédés et systèmes (LIPPS)

Établi en 1998, le Laboratoire d’ingénierie des produits, procédés et systèmes regroupe plus de 95 membres et est considéré comme un leader dans son domaine au Canada. Le LIPPS mène des recherches afin de produire, valider et optimiser des produits, des procédés et des systèmes de fabrication. Il met de l’avant une approche pluridisciplinaire faisant appel à des notions du génie mécanique, du génie logiciel et du génie industriel.

Le LIPPS se distingue par sa démarche qui combine la recherche appliquée et les activités de développement industriel.

La recherche

Les recherches du laboratoire s’articulent autour de deux axes complémentaires issus du contexte industriel moderne.

Axe 1 : Domaine physique (matériaux, outils, procédés)

- Optimisation des procédés de fabrication (usinage, soudage, meulage, prototypage rapide, moulage et MOCN)

- Usinage à haute vitesse et usinage propre (usinage respectant l'environnement et la sécurité du travail)

- Instrumentation et contrôle des procédés et des produits (contrôle non destructif)

- Métrologie et inspection automatique (CMM, postprocesseur, vision et scanner laser)

- Caractérisation des matériaux

- Recyclage et réutilisation des matériaux

- Essais de durée de vie des outils et d'usinabilité

- Mise en forme des matériaux et des composites

Axe 2 : Domaine virtuel (CAO/FAO, numérisation et optimisation de la fabrication)

- Conception pour la fabrication et l'assemblage efficaces

- Méthodes, modèles et outils pour l'ingénierie intégrée (CAO, FAO, EF, gestion intégrée des données techniques)

- Gestion des variations dimensionnelles et géométriques (tolérancement, gammes de fabrication, capabilités des procédés)

- Gestion du cycle de vie des produits et gestion des changements d’ingénierie

- Design des expériences (DOE), analyses statistiques des données et optimisation

- Usinage haute performance de pièces aéronautiques en alliage léger

- Gestion intégrée des changements dans le processus de production

- Approche pluridisciplinaire de l’optimisation de la standardisation pour l’intégration et la configurabilité

- Usinage sans poussières des composites

- Inspection et tolérancement géométrique des pièces flexibles

- Représentation formelle des procédés d'usinage multiaxes pour la génération de caractéristiques d'usinage

- Lien technologique de dérivation dans la capture et l’exploitation des contraintes produit-processus

- Fabrication des pièces axisymétriques avec profil complexe en acier à haute résistance

- Développement d’un détecteur de plagiat pour la CFAO

- Amélioration des procédés de fabrication des prothèses plantaires

- Prédiction de l’effet des contraintes résiduelles en usinage à haute vitesse

- Optimisation du processus de gestion des variations géométriques appliquées sur les structures métalliques mécano-soudées

- Analyse des systèmes de mesure de la ligne de production des batteries LPM

- Fiabilisation résiduelle des turbines hydrauliques

- Caractérisation des alliages du cuivre

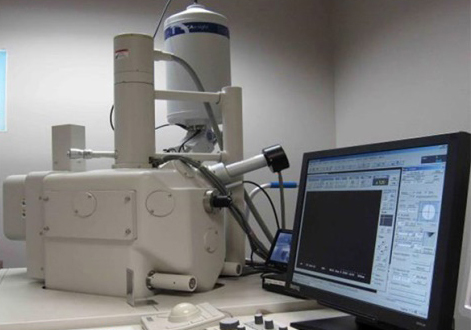

Le laboratoire de caractérisation des matériaux est unique en son genre. Complètement intégré aux travaux de recherche portant sur la fabrication propre, il comprend entre autres :

- Microscope à force atomique (AFM)

- Microscope électronique à balayage à pression variable

- Microscope confocal à balayage laser

- Caméra de haute vitesse jusqu'à 120 000 fps

- Spectroscope infrarouge à transformée de Fourier (FTIR)

- Machine de compression / haute tension de déformation : 200 kN

- Machine de traction / compression / torsion linge + salle de l'environnement

- Système d'analyse thermique et thermogravimétrique (DTA, TGA : 25 °C à 1500 °C)

- Analyseur de gaz

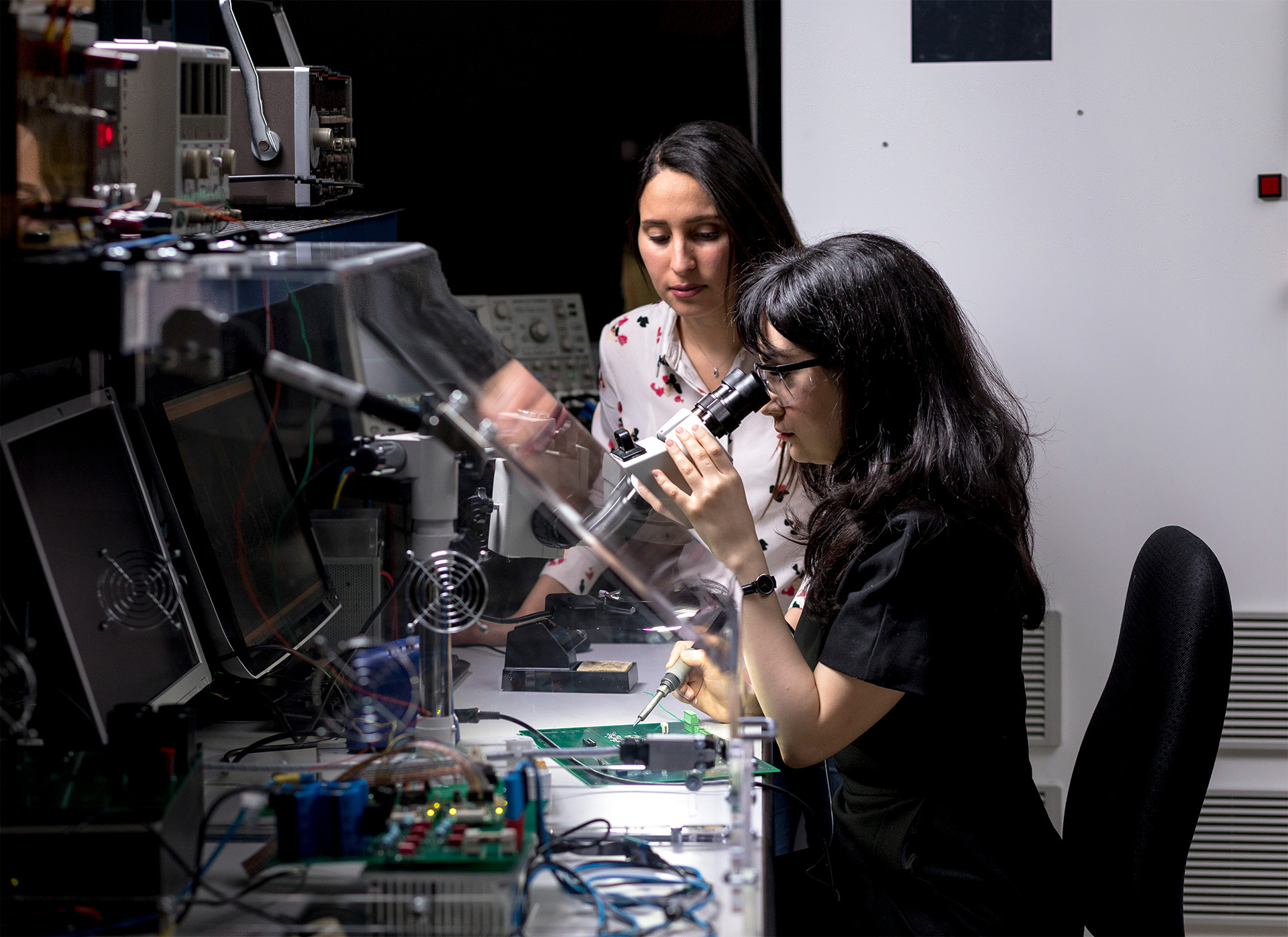

Le laboratoire de fabrication possède des équipements industriels à la fine pointe de la technologie de production et de conception ainsi que de mesure dimensionnelle. Ses ordinateurs disposent de logiciels CAO/FAO/IAO. Il comprend entre autres :

- Tour fraiseur CNC INTEGREX 200 IIIST (Mazak, 2004)

- Fraiseuse CNC à très haute vitesse Huron K2X10 (Huron Graffenstaden, 2007)

- Fraiseuse CNC à 3 axes NEXUS 410A (Mazak, 2004)

- Fraiseuse CNC à 3 axes NEXUS QT100 (Mazak, 2007)

- Fraiseuse CNC à 5 axes Hitachi-Seiki VS50 (1998)

- Fraiseuse CNC à 5 axes Mazak Variaxis i-500 (Mazak, 2013)

- Robot industriel à forte charge KUKA KR 160 R1570 Nano (Kuka, 2014)

- Prototypeur rapide par dépôt de matière en fusion Prodigy Plus (Stratasys, 2001)

- M.M.C. (C.M.M.) 5 axes Bright Strato 7106 (Mitutoyo, 2004)

- Microscope numérique Keyence VHC-500F (Keyence, 2011)

- Testeur d’état de surface Mitutoyo SJ400

- Scanners 3D portables Creaform EXAscan (2011 et 2015)

- Dynamomètre à 3 axes Kistler 9255B

Notre équipe

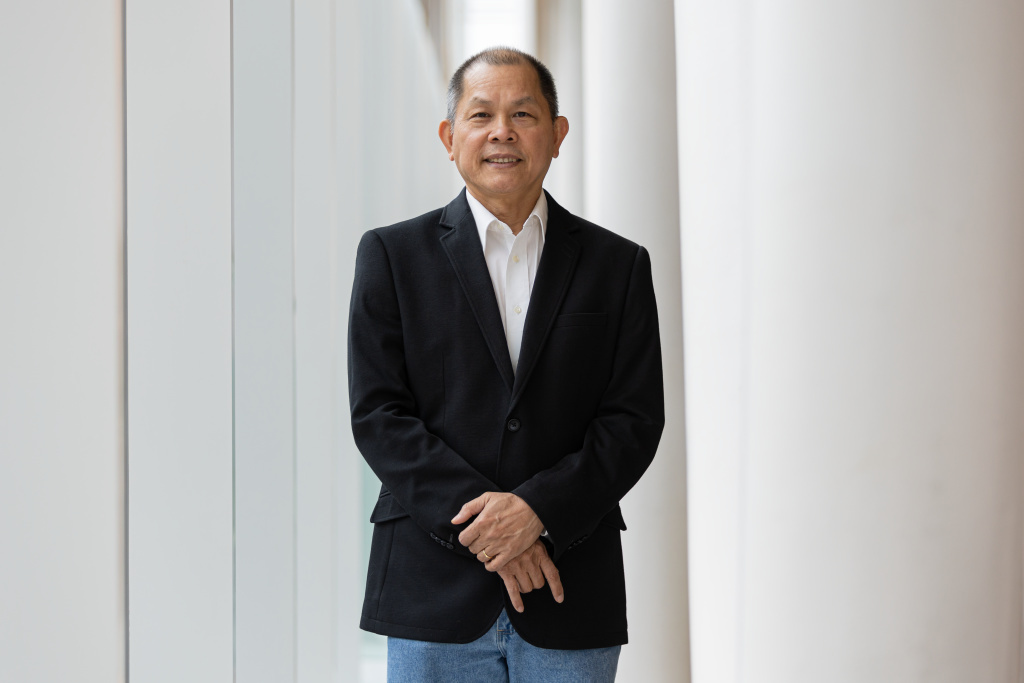

Hosny Fawzy Samuel

Professeur associé, Département de génie mécanique

Personnel de recherche

- Mahshad Javidikia, Ph. D., assistant de recherche

- Jules Kouam, Ph. D., associé de recherche

- Morteza Sadeghifar, Ph. D., associé de recherche

- Davood Shahriari, postdoctorat, chercheur

Partenaires institutionnels

- Centre de recherche sur l’aluminium (REGAL)

- Chaire de recherche industrielle en technologies de mise en forme des alliages à haute résistance mécanique (CM2P)

- Conseil de recherches en sciences naturelles et en génie du Canada (CRSNG)

- Consortium de recherche et d'innovation en aérospatiale au Québec (CRIAQ)

- Fondation canadienne pour l’innovation (FCI)

- Fonds de recherche du Québec - Nature et technologies

- Institut de recherche Robert-Sauvé en santé et en sécurité du travail (IRSST)

- Mitacs

Partenaires industriels

Nous joindre

La recherche à l'ÉTS

L’ÉTS offre un environnement idéal pour penser et créer ce qui pourrait changer le monde de demain.